According to the US Geological Survey, approximately 19 million tons of copper is produced annually, with Chile accounting for 27% of it. Copper mining is one of the principal sources of copper toxicity. The Dartmouth Toxic Metals writes: “Roughly half of the hazardous wastes sites on the EPA’s National Priorities List are known to contain copper. Air and soil near copper processing facilities such as smelters typically have much high levels of copper than that in other areas. Agricultural runoff can contain copper-based pesticides.” World Atlas offers us an insightful analysis of copper toxicity in agriculture in particular. “The use of pesticides such as “Bordeaux mix,” a fungicide using this metal, also introduces more copper compounds into the environment and may affect humans consuming unwashed fruits or vegetables sprayed with such pesticides.” Furthermore, “copper used in plumbing dissolves gradually and adds the metal into the water supply. Other sources of copper pollution include fossil fuel burning, used motor oils, paint, and wearing out of brake pads. In rare cases, copper IUDs, a non-hormonal form of birth control, have been identified as the cause of copper poisoning in individuals.”

Ocean acidification is one of the direct results of copper toxicity. According to a study by Pablo P. Leal et al. published in Nature, “Metals such as Cu2+ can form inorganic complexes with CO32−, OH−, and Cl−, and organic complexes with organic ligands (L) such as thiols, exopolysaccharides and humic substances. OA will reduce seawater CO32− concentrations and thus the stability of reaction constants in the formation of organic complexes: the toxic free ionic form of copper (i.e., speciation of Cu2+) in the oceans is thus predicted to increase by >50% by the end of the current century.”

Ocean acidification is one of the direct results of copper toxicity. According to a study by Pablo P. Leal et al. published in Nature, “Metals such as Cu2+ can form inorganic complexes with CO32−, OH−, and Cl−, and organic complexes with organic ligands (L) such as thiols, exopolysaccharides and humic substances. OA will reduce seawater CO32− concentrations and thus the stability of reaction constants in the formation of organic complexes: the toxic free ionic form of copper (i.e., speciation of Cu2+) in the oceans is thus predicted to increase by >50% by the end of the current century.”

Image Credits: Anglessy Copper Stream - Wiki Media Commons

Another study (by Ayanleh Mahamoud Ahmed et al.) on the impact of copper on the microbial community structure of river sediment states: “Exposure to Cu had rapid marked effects on the structure and most of the functions of the exposed communities. Exposure to As had almost undetectable effects, possibly due to both lack of As bioavailability or toxicity toward the exposed communities. However, when the two metals were combined, certain functional responses suggested a possible interaction between Cu and As toxicity on heterotrophic communities….Taken together, these findings reveal that metal contamination of sediment could impact both the genetic structure and the functional potential of chronically exposed microbial communities. Given their functional role in aquatic ecosystems, it poses an ecological risk as it may impact ecosystem functioning.”

And yet, importantly, copper toxicity as a result of mining is not a modern phenomenon. “The environmental impact of mining and metallurgy is an issue that has affected societies in the ancient Near East over the past 8000 years. Due to the simultaneous production of agricultural goods and copper metallurgy throughout the last 6000 years in the valley, environmental pollution and its consequences for human health have been considered as a factor in settlement abatement”, writes Kyle A. Knabb et al. in their paper on the ecological impact of ancient copper mining. However, given that modern life, unlike earlier times, is increasingly, almost exclusively, dependent on mining and metallurgy, the impact is far more disastrous.

Health Hazards of Copper Mining, Collecting and Processing

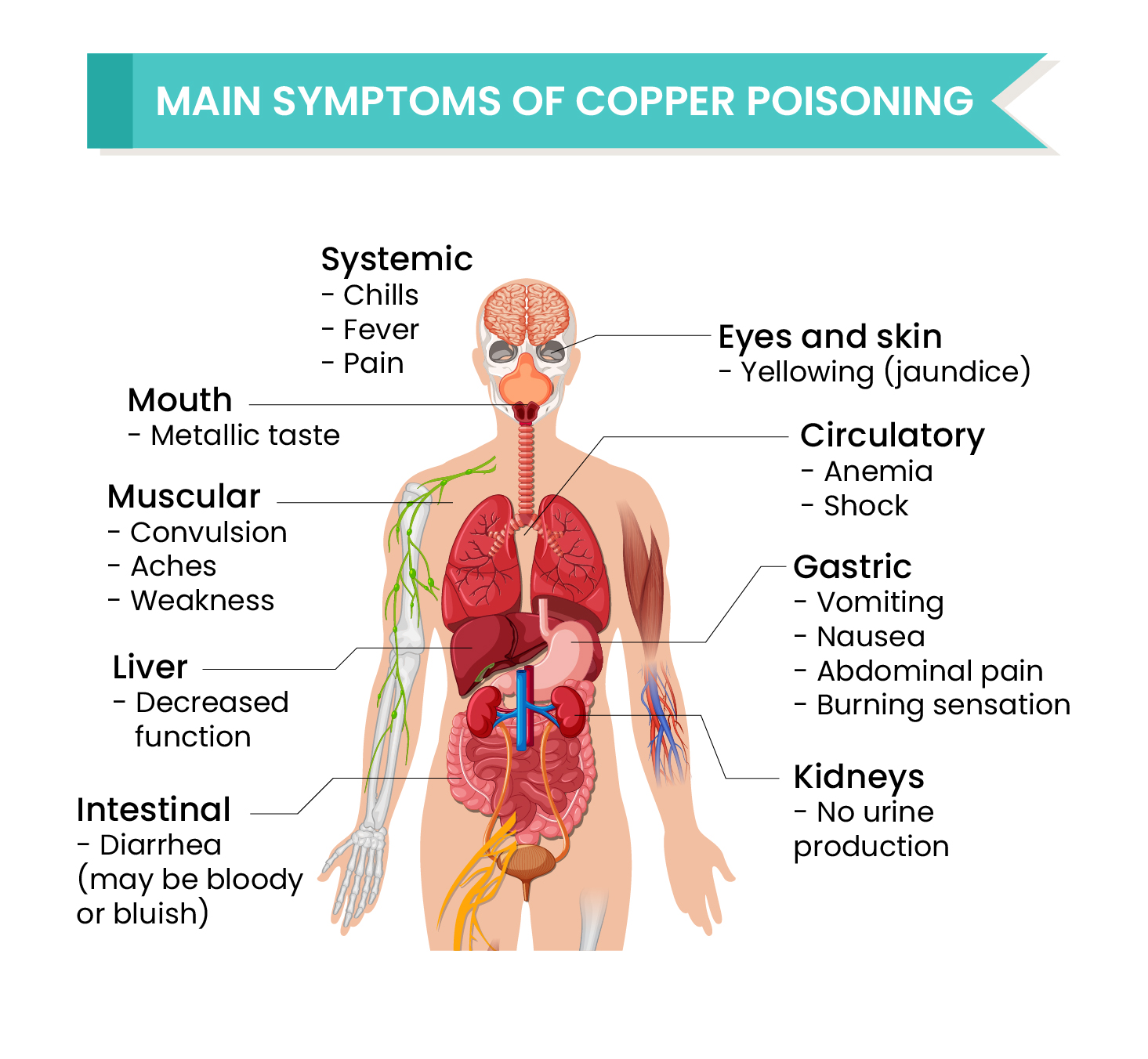

One of the largest copper mining companies in Zambia recorded 165 injuries and 20 fatalities between 2005 and 2007. Underground workers were found to be most susceptible to injuries and fatalities resulting from rock fall, explosions, wind blasts, and wet-fill release. According to the Zambian Business Times, there were 13 deaths in the country’s mining industry in 2016. In 2008, the government charged and fined the manager of the Mopani Copper Mines (Zambia) for polluting the Mufulira water system. “Local clinics registered over 1,000 residents affected by the spill, who complained of abdominal pains, diarrhea and vomiting” (Danwatch).

Deep underground mining triggers heat stroke and heat rash (miliaria rubra). According to an analysis of underground heat by Larry Malambo (2014), “The temperatures are mainly caused by auto compression, heat conducted through rock strata and fissure water; toxic fumes from blasting and exhaust fumes from diesel equipment i.e. loaders and dump trucks. The working conditions are further worsened by leaking ventilation ducts, air resistance in airways, wrong installation and positioning of the fans and recirculation of air. These high temperatures reduces productivity and has an adverse effect on the health and safety of underground personnel.”

Studies have shown increased rates of lung cancer in copper miners. Silicosis is a major health issue in Chilean copper mines. “SkoczyÅska et al. (2016) provides evidence for variation in lung function according to the activities undertaken in a Polish copper mine, with welders being particularly affected” (OECD, 2019, Dr. Mike Holland). Furthermore, “evidence has also shown accelerated silicosis in rheumatoid arthritis and of renal disease following prolonged exposure and there is also evidence that it can lead to lung cancer.” (K. Amponsah-Tawiah et al. Safety Science, 2014). The latter study also notes the impact of heat on miners: “With the rock temperature increasing 1 degree C every 100 m in depth and increasing geothermal gradient along with auto-compression of the air chamber further increases the mine temperature.” Chemical hazards include exposure to diesel particulate, arsenic during copper smelting, and hydrogen cyanide gas during hydrometallurgy.

Miners experiencing whole-body vibrations while operating heavy mobile equipment are at risk of contracting (or exacerbating) spinal disorders. Heavy lifting, vibration tools, repetitive work, static postures etc. trigger a slew of musculoskeletal injuries. According to a study on injuries affecting underground miners in Kitwe, “heavy lifting was the most frequently reported risk factor followed by awkward posture and repetition.” Children living close to copper mines are susceptible to asthma and rhinoconjunctivitis. “Bjerre et al (1993) in their study in Falun, Sweden found that children up to four years of age showed significantly increased blood lead levels during the period of the study…” (London School of Hygiene & Tropical Medicine).

“In a nation wide survey of heavy metal absorption in children aged 1-5 years of age living near copper-lead-zinc smelters in 19 U.S towns (Baker, Hayes et al. 1977) found increased systemic absorption of arsenic reflected by urine arsenic content, in children near 10 of 11 copper smelters” (Carolyn Stephens & Mike Ahern, 2001, London School of Hygiene & Tropical Medicine). A 1983 study found increased mortality rates from non-malignant respiratory ailments in copper mining and smelting countries. Investigations on community pollution resulting from copper mining and smelting recorded an excess of deaths by lung cancer and digestive ailments in men and endocrine and metabolic disorders in women. World Atlas writes: “According to the US Department of Health and Human Services, very high copper doses can damage the kidneys and liver and may lead to death. There is also a correlation between some aging effects and excess copper.”

Artisanal mining (in which miners are not officially employed by the mining company and use their own resources for mining) is the hotbed of occupational hazards. “Artisanal mining can be a desperate business. On top of suffering harsh work conditions, many creuseurs – meaning “diggers,” as the miners are known locally – are ruthlessly exploited by traders...” (Audrey Gaughran, Amnesty International, 2013). Lack of proper mine sanitation gives to rise to concentrated outbreaks of leptospirosis and ankylostomiasis. Workers operating in remote mining grounds are threatened by tropical diseases such as malaria and dengue. According to a study on the impact of Covid-19 on artisanal mining in the Democratic of the Congo, “The disparity between the Copperbelt’s mineral wealth and the poverty of its citizens is jarring. The informality and illegality in the copper-cobalt sector represent significant obstacles to establishing effective domestic and international support intervention. Moreover, due to Covid-19, challenges in cobalt and copper production, export and trade have increased.” The study further notes: “Copperbelt miners are moving from cobalt to copper because of cobalt’s decreased market price…other factors, like international scrutiny, could have more of an impact on miners’ livelihoods than COVID-19. A dearth of actors in the supply chain has decreased the cobalt price and has led to fewer opportunities for employment. The main concern regarding the impact of COVID-19 on the copper and cobalt supply chains in the eastern DRC is the impact on the global and trade markets, which in turn has affected mineral prices.” Citing the World Bank, Fernando P. Carvalho (Mining industry and sustainable development: time for change, 2017) writes: “It is widespread in developing countries in Africa, Asia, Oceania, and Central and South America, and it ensures the existence for millions of families in rural areas of developing countries. Globally, about 100 million people – workers and their families – depend on artisanal mining compared to about 7 million people worldwide engaged in industrial mining.”

Psychological hazards include fatigue from overwork (most mines operate 24x7), drug and alcohol abuse, and post-traumatic stress disorders. “Registered managers often feel personally responsible for such injuries, even in the absence of negligence, and face the ordeal of government inquiries and legal proceedings” (Occupational health hazards in mining: an overview, A.M. Donoghue, 2004). Much depends on the age of the workers. According to K. Amponsah-Tawiah et al. (in their review of the mining industry in Ghana), “older mine workers (over 45 years) were at a greater risk of having occupational injuries, which was attributed to a decrease in their physical and mental abilities which subsequently diminished their ability to perform highly demanding tasks properly and be sufficiently attuned and alert to environmental mining hazards. Other studies report that younger workers can also be at a greater risk of mining injuries as their lack of experience can contribute to a lack of knowledge which leads to a greater propensity to engage in risk taking behaviors.” A study by José Ignacio Méndez on the psychosocial risks in a Chilean copper identifies the following recurring events: violence and harassment at work, “gender-related psychosocial risk conditions (women working in mining), and mining culture related situations: hierarchies, relation with subcontractors, superstitions and many others”. Another study on the Cananea copper mine in Mexico identified a number of inconsistencies such as “inadequate respirators, ear plugs, no pulmonary or audiometric test, lack of training programs,” and almost zero air-and-noise monitoring.

According to the United States Environmental Protection Agency (EPA), Technologically Enhanced Naturally Occurring Radioactive Material (TENORM) is defined as, "Naturally occurring radioactive materials that have been concentrated or exposed to the accessible environment as a result of human activities such as manufacturing, mineral extraction, or water processing.” Copper mining waste significantly “exposes and concentrates” radioactive materials resulting from different stages of extraction and processing. Pyrites and sulfides exacerbate radionuclide leaching. Exposed to air, pyrites and sulfides form sulfuric acid, triggering mobilization of heavy metals, such as uranium, which in turn leads to acid mine drainage (AMD).The EPA writes: “The Arizona Department of Environmental Quality (ADEQ) shared the results of radiological surveys with EPA on TENORM emanating from copper mines in mid-1992. These surveys show that radionuclide concentrations vary, from near-background levels to above maximum contaminant levels, across the state, including increases of up to 100 times background levels for all radiochemicals tested except radon-222.” In 1992, the Surface Water Enforcement Section of ADEQ (Association for the Development of Environmental Quality) “found two more mines where TENORM had affected surface waters in Arizona’s Cerbat Mountains (ADEQ, 8/1993). The De La Fontaine and the American Legion mines are located northwest of Kingman, in the Stockton Hills or Hualapai Pines mining district. The mines are on different branches of the same stream and are both free-flowing sources of AMD that are impacting surface water.”

In-situ leaching has been shown to transport heavy metals into the groundwater. “Copper smelting and refining facilities produce 2.5 million metric tons (MT) of smelter slag and 1.5 million MT of slag tailings per year” (EPA). Groundwater samples from Arizona mines have been found to contain raffinate which is generally stored in ponds before being recycled as a leaching solution. Scientists at the University of Manchester and the University of Colorado highlight the impact of mining on water quality and quantity: “Companies insist that the use of modern technologies will ensure environmentally friendly mining practices. However, evidence of the negative environmental impacts of past mining activity causes local and downstream populations to worry that new mining activities will adversely affect their water supply...There are major stakes in these conflicts, affecting everything from local livelihood sustainability to the solvency of national governments. Fears for water quantity and quality have triggered numerous and sometimes violent conflicts between miners and communities.”

E-waste contains large amounts of copper. A review by Kristen Grant et al. on the health consequences of exposure to e-waste says: “Informal electronic waste recycling includes the dismantling of end-of-life electronics to retrieve valuable elements with primitive techniques, without or with very little technology to minimise exposure or protective equipment, allowing the emission of dangerous chemicals.” Informal waste processing amplifies the health hazards of improper waste management. The Eurometaux reported that around two-third of electronic waste from the European Union is not properly recycled. One of the most reported instances of informal waste processing is burning insulation from copper wire. Workers involved with e-waste processing are highly vulnerable to contamination from burnt copper wires. The province of Saskatchewan in Canada has strict regulations for copper wire handling. “Metal recyclers and salvage yard operators should not accept copper wire where there are signs or suspicions that the copper wire insulation has been burned off. Knowingly purchasing or receiving burned copper wire may result in enforcement action or incurring liability should contamination occur. Storage of burned copper wire could be a violation of The Hazardous Substances and Waste Dangerous Goods Regulations. Operators should refuse receipt of burned copper wire and report the attempted sale to the ministry.”

Environmental Impact of Copper Mining

Over the last 10 years, the total energy consumption at copper mines has gone up by 46%, exceeding the rate of production during the same time by 15%. The declining ore quality has only fueled the rate of waste generation at mines. “Analyzing only copper mines, the average ore grade has decreased approximately by 25% in just ten years…the decrease in ore grades observed before for those same mines also entails an increase in energy consumption, as more gangue mineral has to be removed from the ore to produce the same amount of concentrate.” (Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality?: Guiomar Calvo, Gavin Mudd, Alicia Valero, Antonio Valero, 2016).

The degree of environmental pollution depends on how well-regulated the mining environment is. The Marcopper mining disaster of 1996 in the Philippines was caused by a leakage in the drainage tunnel which released 1.6 million cubic meters of tailings into the fluvial network, inundating villages with sludge and destroying coral reefs. Accidental release of sulfuric acid from the Buenavista copper mine in Mexico contaminated the drinking water supply of local residents by flowing into the Sonora River. According to one estimate, the Konkola mine in Zambia generates 93,000 tons of mine waste annually. The La Oroya copper mine in Peru, in operation since 1922, has been a major source of cadmium- and lead-contamination. “A study of 93 newborn children in the first 12 hours of their life, conducted by Hugo Villa, showed they had highly dangerous levels of lead in their blood, inherited from their mothers while in the womb. The nearer the mothers lived to the main smelter, the higher was the babies’ level of lead poisoning” (Hugh O’Shaughnessy, The Observer, 2007). According to the Blacksmith Institute, in terms of environmental degradation, La Oroya ranks alongside the Chernobyl disaster.

“Tailings ponds are typically formed by locally derived fills (soil, coarse waste, or overburden from mining operations and tailings) and the dam walls are often built up on to sustain greater amounts of tailings” (Wikipedia). To produce 1 ton of copper, 150 tons of ore needs to be excavated, crushed, and extracted. The process generates large amounts of tailings loaded with highly toxic metals and metalloids. Tailings may be deposited on natural surfaces without embankments. The Valea Åesei in the Apuseni Mountains in Romania is a case in point. “It was created as a consequence of the open pit Rosia Poieni Cu ore exploitation initiated in 1986 and encompasses an area of the former GeamÄna village (Milu et al. 2002), now almost entirely engulfed in tailings. Only a few inhabitants still live in the direct vicinity of the impoundment, the rest having been relocated. As the mine operates, the valley is systematically flooded by tailings and mine water while buildings of the former village are literally drowned in waste, from which the tower of its historical church can still be seen partially protruding” (Piotr Rzymski et al. 2007).

Future mining projects are accused of being heedless of the precedents of environmental contamination by copper mines. The proposed open-pit Rosemont copper mine in Arizona is an example. According to climate activists, the proposed mine poses a threat to the local biodiversity. It will consume roughly 6000 acre-feet of potable water annually, which amount could be diverted for daily household needs of around 50,000 people. The proposed mine will endanger the habitat of the El Jefe, “the last known living wild jaguar” in the USA. There is also the risk contamination of water supplies by mercury, arsenic, and lead. “After the life of the mine, estimated at 19 years, the pit lake would form…The lake would eventually grow to a surface area of 213 acres (three-times the size of the Superdome), containing about as much water as Tucson uses each year. But continual evaporation and refill would concentrate metals and other chemicals. Years in the future this would create a toxic environment for many animals, exceeding chronic exposure standards for cadmium, copper, zinc, and selenium” (‘In a Land of Wild Cats’, National Geographic, April, 2019).

Deep-sea copper mining has been recognized as a possible threat to the environment. The “Nautilus Minerals is working in the territorial waters of Papua New Guinea to shatter a field of underwater hot springs lined with precious metals, while Japan and South Korea have embarked on national projects to exploit their own offshore deposits” (The Atlantic, Feb 2020). The local community highlighted potential risks of deep-sea mining, such as tsunamis and a dwindling shark-population. According to the Nautilus Minerals, waste generated during copper processing is supposed to benefit local industries, although experts cite a gaping lack of evidence on the ground. 16 global mining companies, including the Nautilus Minerals, have already signed contracts for deep-sea mineral exploration.

The impact of sulfide-ore copper mines on the environment is equally considerable and worrying. From pipeline spills to faulty treatment methods, copper sulfide mines have a disastrous track record. A 2012 study of 14 copper sulfide mines in the US highlighted instances of rampant water pollution. According to Earthworks, “All of the mines (100%) experienced pipeline spills or other accidental releases. The most frequent spills were reported at the Ray Mine in Arizona, where over fifty pipeline spills occurred from 1988 to 2012… At 13 of the 14 mines (92%), water collection and treatment systems have failed to control contaminated mine seepage, resulting in significant water quality impacts.” Severe acid mine drainage is expected to cause water pollution in perpetuum. Earthworks says: “Due to the severity of water quality impacts from acid mine drainage, many hard rock mines across the west require water treatment in perpetuity. Even with existing technology, acid mine drainage is virtually impossible to stop once the reactions begin. To permit an acid generating mine means that future generations will take responsibility for a mine that must be managed for possibly hundreds of years.”

The Bingham Copper Mine is a typical case. “Mine operations have resulted in a plume of contaminated groundwater extending over 70 square miles, and the State of Utah filed a natural resource damage claim against the mine in 2008 for impacts to water and wildlife resources” (Earthworks). Tailings spills at the Pinto Valley Mine and the Tyrone Mine resulted in the contamination of local river basins. Abandoned copper mines trigger acid mine drainage. For instance, the Cyprus Mine Operation (located in Northern Cyprus), which operated from 1914 to 1974, has been found to cause substantial acid mine drainage.

Copper mining is one of the biggest sources of fugitive emissions. The U.S. Environmental Protection Agency defines fugitive emissions as “those emissions which could not reasonably pass through a stack, chimney, vent or other functionally-equivalent opening.” The principal sources of fugitive emissions include fugitive soot and dust, blasting, drilling, vehicles on construction roads, tailings ponds, leach pads, etc. Mine dewatering is a major cause of concern. As stated in a study commissioned by The European Union: “….once mining operations end, the removal and management of mine water often end, resulting in possible accumulation in rock fractures, shafts, tunnels, and open pits and uncontrolled releases to the environment…Ground water drawdown and associated impacts to surface waters and nearby wetlands can be a serious concern in some areas.” The same study elucidates the impact of dewatering: “…degradation of surface water quality and beneficial uses; degradation of habitat (not only riparian zones, springs, and other wetland habitats, but also upland habitats such as greasewood as ground water levels decline below the deep root zone); reduced or eliminated production in domestic supply wells; water quality/quantity problems associated with discharge of the pumped ground water back into surface waters downstream from the dewatered area.”

Another study commissioned by the European Union has shown the adverse impact of copper mining on soil quality and plant life. Copper mining operations “routinely modify the surrounding landscape by exposing previously undisturbed earthen materials. Erosion of exposed soils, extracted mineral ores, tailings, and fine material in waste rock piles can result in substantial sediment loading to surface waters and drainage ways. In addition, spills and leaks of hazardous materials and the deposition of contaminated windblown dust can lead to soil contamination.” The International Journal of Modern Sciences and Engineering Technology (IJMSET) published a critical review (2015) of the effects of copper dust on soil quality in India. “Some of the direct toxic effects caused by copper metal concentration include inhibition of cytoplasmic enzymes and damage to cell structures due to oxidative stress. For instance, a reduction in the number of beneficial soil microorganisms may also indirectly affect the growth of plants.” The authors emphasized “growth retardation” and “leaf chlorosis” as the two major consequences of copper mining on plant life.

Over the years, experts have come to understand the relation between copper mining and migration (human and animal). “Pollution from a base metal mine on a tributary of the Northwest Miramichi River caused many adult Atlantic salmon, which were on their normal upstream spawning migration, to return prematurely downstream through a counting fence on that river during summer and early autumn” (Effects of copper-zinc mining pollution on a spawning migration of Atlantic salmon, Richard L.Saunders and John B.Sprague). The International Institute for Environment and Development offers us an insight into the impact of copper mining on human migration: “…at the Grasberg mine in Indonesia the local population increased from less than 1000 in 1973 to between 100,000 and 110,000 in 1999. This influx of newcomers can have a profound impact on the original inhabitants, and disputes may arise over land and the way benefits have been shared. (These were among the factors that led to violent uprisings at Grasberg in the 1970s and the 1990s)”. The same study highlights the long-term effects of migration: “Improved infrastructure can also bring an influx of settlers. For instance, it is estimated that the 80- meter-wide, 890-kilometre-long transportation corridor built from the Atlantic Ocean to the Carajas mine in Brazil created an area of influence of 300,000 square kilometres.” The Carajas Mine is an iron-ore mine.

Human displacement and resettlement has huge impacts on collective social values. In his paper on mining-induced displacement, Bogumil Terminski writes: “At least five percent of development-induced displacement is caused by mining. It seems obvious, then, that mining-induced displacement and resettlement should be recognized as a fully autonomous category of development-induced displacement and resettlement." In discussing the impact of copper mining on the environment, the author notes: “It is estimated that the exploitation of environment led in Grasberg area, for more than 30 years, has damaged 30,000 hectares of rainforest as well as the Kopi and Ajkwa rivers. The risk of displacement of the population also affects the region of East Kalimantan in Indonesia.” The paper also recognizes the rise of mining-induced displacement in Africa: “Nowadays, open-pit mining is a significant environmental and social problem in Africa. The mining of coal, copper, iron, gold, bauxites, and diamonds is a common cause of highly visible environmental degradation and development-induced displacement and resettlement...According to the official report of the Southern African Development Community, ‘mining-induced displacement [...] was one of the most underreported causes of displacement in Africa, and one that was likely to increase, as mineral extraction remained a key economic driver in the whole region.’” Terminski notes the impact of mining-induced resettlement on Zambia: “According to Sonnenberg and Munster (2001), 750 people from 143 households had been resettled at that time by mining operations. The affected people (67 households) were moved to Ming’omba village on 14 January, 2002. In February 2002, 74 households from Kawama were resettled.”

The International Institute for Environment and Development says: “Entire communities may be uprooted and forced to shift elsewhere, often into purpose-built settlements not necessarily of their own choosing. Besides losing their homes, communities may also lose their land, and thus their livelihoods. Community institutions and power relations may also be disrupted.” The impact of displaced communities is particularly worrying: “Displaced communities are often settled in areas without adequate resources or are left near the mine, where they may bear the brunt of pollution and contamination. Forced resettlement can be particularly disastrous for indigenous communities who have strong cultural and spiritual ties to the lands of their ancestors and who may find it difficult to survive when these are broken.”

Managing the Environmental Impact of Copper Mines

Managing the environmental impact of copper mining is possible. Dr. Mike Holland writes: “An Environmental Impact Assessment for the Lumwana mine in Zambia (ECVL, 2005) identifies a series of negative impacts relating to physical disturbance of the land, environmental contamination from routine and accidental releases, inadequate waste management and sewage treatment and disposal and noise. ECVL states that ‘These potential environmental impacts with the exception of permanent changes to the physical landscape resulting from open pit excavation, tailings storage facility, water dam, river diversion and waste rock dump construction can be prevented or successfully mitigated against by implementation of a sound environmental management plan.’ The company then provides details of how it intends to manage the risks.” Illustrating the success of prompt management systems, Holland draws attention to a case of accidental release in Zambia: “Acid spilled from a tanker following an accident entered the nearby river, killing fish. The acidity was neutralized, and the Zambia Environmental Management Agency and local residents were informed. Of course, whilst systems appear to have worked to resolve contamination after the accident, questions remain as to how the accident happened and the design of the tanker, in allowing strong acid to be released.”

In their report Copper: Technology and Competitiveness (published by the Office of Technology Assessment, 1988), the authors offer a number of recommendations such as “minimization, collection, and treatment of mine drainage, mill process water, and contaminated surface drainage; 2) handling, storage, and ultimate disposal of tailings and waste rock; and 3) reclamation of the site to minimize long-term environmental effects once active mining has ceased. Waste reprocessing and utilization is a fourth method that could offer many advantages over disposal, but the enormous volumes of waste preclude this from being a viable alternative to disposal…Tailings may be reprocessed to recover additional metals. This method may be particularly rewarding when dealing with older tailing piles from much less efficient beneficiation processes. Tailings also may be used onsite for mine backfill. There has been extensive research into the possibility of upgrading tailings to a salable product such as building materials (e.g., glass and bricks).”

Importantly, Holland takes note of the limitations of environmental regulation programs: “There is evidence, however, that management and pollution control systems do not always work. Release of acid from the Mopani mine in Zambia into the local water network following failure of a pump in 2008, is said to have affected over 1000 residents with abdominal pains, diarrhea and vomiting12. There is also the question of when controls are fitted: problems of SO2 emissions from the Mopani mine in Zambia persisted for over 70 years, before an improved sulfur recovery unit (increasing rates from 50% to 97%) was installed in 2014.” The authors of Copper: Technology and Competitiveness write: “As with all other industrial activities in the United States, copper production is subject to extensive environmental regulation related to air and water quality, and materials handling and disposal practices. This regulation has had significant impacts on the mode and cost of domestic copper production.” Which raises the question: how far are regulations compatible with the interests of domestic copper producers?

Speaking of sulfur dioxide emissions control, the authors mention The Clean Air Act which “established National Ambient Air Quality Standards for six pollutants (see table 8-2). The Act requires that these standards be met throughout the United States, including the improvement of air quality in “dirty” areas and the prevention of significant deterioration of air quality in “clean” areas. These goals are achieved through emission limitations on various types of sources (including non-ferrous smelters) that require the use of technology-based controls. The Act also regulates emissions of hazardous pollutants. Substantial financial penalties are imposed for non-compliance.” This has led to the rise of acid plants in the US because “the technology is well proven and is the least expensive method of smelter SO2 control. Sulfuric acid is used in solution mining, and also is the most common form in which other industries consume sulfur; thus it can be a salable byproduct rather than a waste.” However, “non-leaching markets for sulfuric acid generally are a long way from the smelters in the United States, and the resulting transportation costs can turn the byproduct credit into a deficit. Moreover, it often is cheaper for industrial consumers to buy sulfur and produce the sulfuric acid themselves than to purchase acid produced elsewhere.”

The authors draw attention to SO2 emissions control in Japan and Latin-American nations: “In some countries, such as Japan, a very high level of SO2 control is achieved by copper smelters as part of a government policy to provide sulfuric acid for industrial development. In less developed areas, such as the copper-producing countries of Africa and Latin America, there are few industrial markets for acid, and SO2 control is minimal.”

Importantly, weak SO2 emissions (

Control strategies have been successful. They have “resulted in marked improvements in long term SO2 levels in the past 15 years, with substantial benefits for public health and the environment. According to EPA statistics, copper smelters reduced their total sulfur dioxide emissions from 3.5 million tons in 1970 to 970,000 tons in 1983—a 72 percent reduction. The percent of input sulfur captured at domestic smelters is currently 90 percent.” However, there are costs involved. “Before technological means of control became mandatory, smelters used supplemental and intermittent SO2 controls. While these methods resulted in lower overall SO2 emissions, they also reduced production. When smelters had to install technological controls, many closed because the capital cost of retrofitting the smelter was too high. The General Accounting Office estimates that between 1970 and 1984, 44 percent of the reduced emissions from non-ferrous smelters (including lead and zinc operations) were due to improvements in control techniques, while 56 percent were due to decreased production.” Which brings us back to the question of compatibility. “The primary copper industry had capital investments totaling $2.088 billion for air pollution control between 1970 and 1981, with average annual costs of $3.074 billion. Furthermore, adding an acid plant to the production line increases operating costs without necessarily providing a byproduct credit. Present levels of control entail capital and operating costs of between 10 and 15 cents per pound of copper.” By contrast, “copper smelters in Chile, Canada, Peru, Mexico, Zaire, Zambia and Japan...are not faced with similar environmental regulations. In all but Japan, if smelter emissions are controlled at all, it is only to the extent that sulfuric acid is needed at an associated leaching project. Copper smelters in these countries capture between 0 and 35 percent of the input sulfur; on average only about one-fifth of the present level of U.S. control. Japanese smelters achieve 95 percent control as part of government policy to subsidize sulfuric acid production.”

Are their sustainable ways of harmonizing pollution control and copper productivity? “One of the keys to continuing competitiveness is the ability to innovate, which in turn is dependent on capital formation, or investment in plants and equipment embodying new, more efficient technologies…policy support for continuing competitiveness would have to include both micro- and macroeconomic policies. A consistent and integrated set of government policies can gradually turn a temporary comparative disadvantage in capital- or education-intensive commodities into an advantage...A third option is to provide direct product support...One option for increasing the level of R&D on production technology is for the domestic copper industry to actively pursue cooperative research ventures involving copper companies, vendors, universities, and government agencies...One key to expanding sales is marketing based on product differentiation.”

In their paper on the environmental impacts of copper production in China, Di Dong et al. underscore the importance of technology in managing the environmental costs of copper mining: “Cleaning up copper production processes and improving energy efficiency are further options for reducing impacts. To comprehensively reduce or eliminate environmental pollution, clean production systems should be applied across the board to the entire copper production chain. An extremely important first step is therefore to identify the origins of impacts occurring in the various links in the chain.” While emphasizing the need for innovation, the authors write, “Previous studies have reported a boom in technological innovation in copper production in the mid-20th century. Prior to that, the technology had remained unchanged for 65 years. Truly substantial efficiency improvements are not to be anticipated unless a completely new production process is developed, a perspective that is unlikely to have any impact before 2050.” According to Dong et al., the most sustainable option is “increasing the share of secondary copper production is probably the most important option of all...secondary copper production has lower per-kg environmental impacts. This option hinges on the amount of available copper scrap in China. However, given that domestically generated scrap will only be able to cover just over 50% of demand in 2050, the scope for this option appears to be fairly limited in China…to protect the environment of recycling facilities and achieve high copper recovery rates, the waste management sector needs to reorganize...Against this background, improving the efficiency of copper scrap collection and processing as well as reconsideration of import restrictions stand out as potentially very effective options.”

Since liberalization of trade has been a major contributor to environmental pollution, the UNEP, in a case study on the Chilean copper industry, recommends a number of measures: “Among the main elements that should be considered is the introduction of a long-term perspective to development policy and the integration of economic, social and environmental elements within it. This framework should inform government activities, including legally binding agreements connected to trade—for example, when negotiating the proposed accession of Chile to NAFTA.” Upgrading the current environmental regulatory framework is key: “Going beyond the current approach to environmental protection that focuses principally on point intervention and regulation, the introduction of a broad system of regional planning and management, covering entire ecosystems or river basins, would allow to deal with the interactions between different environmental pressures and the competing demands of economic sectors more effectively. This approach would also make systematic collection of data on the environment and monitoring changes over time feasible.” Speaking of development and transfer of technology, the study notes: “These two elements have been shown to be the most effective means of integrating environmental protection with economic activity. Setting in place explicit provisions to encourage this to take place at a larger scale, both within the mining sector as well as throughout the economy, would contribute to enhancing environmental protection.” The study underscores the need for specific action programs: “The development of a strategy to ensure the transition towards a more sustainable pattern of development in mining areas should be seen as a priority. This would entail exploring development of other forms of economic activity that do not rely solely on nonrenewable resources. Other supportive actions could be to undertake studies on how to address the historically accumulated impacts of mining and issues of similar strategic importance.” Financial stimulus is arguably the most important: “This could be secured by the creation of a fund specifically for this purpose. The mechanisms employed to build up the fund will depend on many factors, but possible options include reform of the tax regime and direct contributions by the mining sector.”

The study notes the urgency of a policy shift. “All levels of human endeavor, and all stages of decision-making are sectoral. The current approach is to try and achieve integration at the level of action by trying to reach a balance among competing interests and needs, all of which are legitimate within their own bounds. Often, none is served adequately, or the strongest sector has primacy. This is what is happening at present, where economic factors are acquiring an ever growing influence over all other aspects of society. A way to address this dilemma may be to integrate the various interests and needs at the initial stage of policy formulation—that is, where goals are defined. At this level, goals should refer to the overall goals of society—not to the narrow, purely sectoral ones.”

In Conclusion

Mining, while being an economically-beneficially activity, insists on an environmental trade-off. From copper mines in Chile to the mining industry in Zambia, the gap between development and sustainability is profound. Add to it the lack of robust and consistent regulatory frameworks and, where such policies are in order, the absence of sincere implementation. The global mining industry presents, therefore, a skewed picture of conviction and apathy. New mining projects are expected to learn from past mining ventures in order to realize the idea of sustainable production. Mining ventures need to establish better links with social communities, human rights aspects, public health, and social development. Furthermore, with the development of technology, future mining must include conservation of environment and effective management of natural resources in their plan of action.

Related Posts

Fishing And Climate Change

The world’s oceans are a crucial component of our planet’s ecosystem, providing

View More

Consumerism And Climate Change

In our fast-paced, modern world, consumerism has become an integral part of our lives. We a

View More

Unraveling Genetic Pollution: Understanding the Environmental Impact of GMOs

What Is Genetic Pollution? Genetic engineering has emerged as a powerful tool in the field

View More